Radiant Heater Fabrication

1500 INR/Square Foot

Product Details:

X

Radiant Heater Fabrication Price And Quantity

- 1500 INR/Square Foot

- 1000 Square Foot

Radiant Heater Fabrication Trade Information

- 7 Days

Product Description

| Material | Cast Aluminium |

| Type Of Location | Industrial |

| Service Duration | 1 Week |

| Service Provided By | Akshar |

| Services Include | Labor & Material |

| Service Type | Radiant Heater Fabrication |

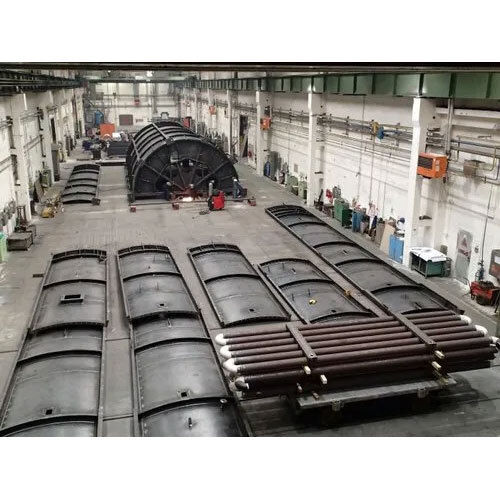

Radiant Heater Fabrication involve designing, cutting, shaping, assembling, and finishing metal or other materials to create bespoke components or structures tailored to a specific application, client requirement, or industrial process.

Precision Engineering for Industrial Heating

Our radiant heaters are crafted using advanced fabrication technology, ensuring precise heat distribution and reliable performance. The rectangular shape and custom sizing options make them ideal for integration into ovens, furnaces, and other industrial heating systems. Surface-mounted installation offers flexibility to suit unique operational needs while maximizing energy efficiency.

Superior Surface Finish for Enhanced Durability

Every radiant heater features a meticulously applied coated or polished finish, enhancing resistance to corrosion and wear. This results in prolonged lifespan and optimal thermal conductivity, making them suitable for repeated use in demanding industrial environments. Our commitment to superior quality ensures heaters maintain their performance over time.

FAQ's of Radiant Heater Fabrication:

Q: How are rectangular radiant heaters fabricated for industrial use?

A: Rectangular radiant heaters are fabricated using high-grade materials and precision engineering techniques. The process includes shaping, surface finishing, and assembling the heaters to meet specific industrial heating requirements for applications like ovens and furnaces.Q: What is the benefit of choosing coated or polished surface finishes for radiant heaters?

A: Coated or polished surface finishes improve the heater's durability by protecting against corrosion and facilitating efficient heat transfer. This ensures a longer lifespan and consistent performance even in harsh industrial settings.Q: When should custom-sized radiant heaters be selected over standard sizes?

A: Custom-sized radiant heaters are ideal when your application requires specific dimensions to fit unique industrial equipment or achieve targeted heating coverage. Standard sizes are suitable for general purpose installations with conventional space constraints.Q: Where are surface-mounted radiant heaters commonly used in industrial settings?

A: Surface-mounted radiant heaters are frequently used in industrial ovens, furnaces, and other heating systems where direct application to surfaces is required for optimized thermal management.Q: What process is involved in mounting these heaters in operational environments?

A: The heaters are installed by securely affixing them onto the required surfaces using specialized brackets or mounting hardware. Their design supports easy integration and ensures stable, efficient operation in various industrial environments.Q: How do radiant heaters improve industrial heating processes?

A: Radiant heaters deliver direct and uniform heat, enhancing temperature control within ovens and furnaces. This leads to improved energy efficiency, reduced heat loss, and better product quality in manufacturing operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email