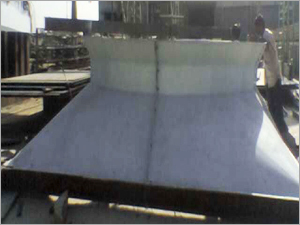

Fin Fan Air Cooled Heat Exchangers

Product Details:

- Temperature Up to 120C

- Air Volume 18000 m/h

- Diameter 38 mm

- Thickness 6 mm

- Number of Pipe 68

- Max. Capacity 5000 kW

- Max Pressure 16 Bar

- Click to view more

X

Fin Fan Air Cooled Heat Exchangers Product Specifications

- 860 kg

- 38 mm

- 18000 m/h

- 2200 mm x 1100 mm x 1750 mm

- New

- Up to 120C

- 5.5 kW

- 380 V

- 5000 kW

- 68

- 10 Bar

- 4500 LPH

- 6 mm

- Horizontal Modular Type

- 16 Bar

- 75 dB(A)

- Easy Access Panels

- Skid Mounted

- High Efficiency Spiral Fins

- Aluminum Finned Carbon Steel

- Axial Flow

- Oil & Gas, Petrochemical, Power Plants

Product Description

Supported by our experienced professionals, we are instrumental in manufacturing, supplying, importing and exporting Fin Fan Air Cooled Heat Exchangers. While manufacturing these heat exchangers, our professional strictly follow norms and standards already laid by the industry. Along with this, premium quality material and latest machines are used to manufacture these Fin Fan Air Cooled Heat Exchangers. Rigorously examined before the final delivery, offered heat exchangers are appreciated for their longer functional life, low maintenance, sturdy construction and outstanding performance.

Superior Heat Transfer Efficiency

This heat exchanger features high-efficiency spiral fins affixed to durable aluminum finned carbon steel tubes, maximizing surface area for improved thermal exchange. The axial flow fan enables consistent air distribution, facilitating reliable temperature control in demanding environments such as refineries and power plants.

Flexible Installation & Maintenance

With a horizontal modular design and skid mounting, the exchanger offers easy placement and relocation. Maintenance is simplified by strategically positioned access panels, minimizing downtime and ensuring operational continuity in fast-paced industrial sites.

FAQs of Fin Fan Air Cooled Heat Exchangers:

Q: How do Fin Fan Air Cooled Heat Exchangers function in industrial applications?

A: These exchangers use axial flow fans to circulate ambient air across aluminum finned carbon steel tubes, efficiently dissipating heat from process fluids. Their high-efficiency spiral fins increase thermal transmission, making them ideal for oil & gas, petrochemical, and power plant usage.Q: What benefits does the modular horizontal structure provide for installation?

A: The horizontal modular structure permits flexible installation and easy relocation. This design is particularly advantageous for sites with evolving infrastructure needs, allowing quick setup and integration with existing systems.Q: When should I perform maintenance on this heat exchanger, and how is it accessed?

A: Routine maintenance should follow manufacturer guidelines or be scheduled at regular intervals, depending on operational demands. Easy access panels are provided, enabling users to inspect and service interior components without extensive disassembly.Q: Where is this heat exchanger typically used?

A: Primary applications include oil & gas production facilities, petrochemical plants, and power generation stations in regions requiring efficient air-cooled solutions, such as India and other global export destinations.Q: What process fluids are compatible with this model, given its pressure and temperature ratings?

A: This model supports a maximum pressure of 16 bar and temperatures up to 120C, making it suitable for cooling a range of process fluids, typically hydrocarbons and industrial liquids with flow rates up to 4500 LPH.Q: How does the high-efficiency spiral fin design enhance cooling performance?

A: Spiral fins increase the contact area for heat transfer, optimizing the removal of thermal energy from process fluids. This results in improved cooling efficiency and lower energy consumption, even under heavy load conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email