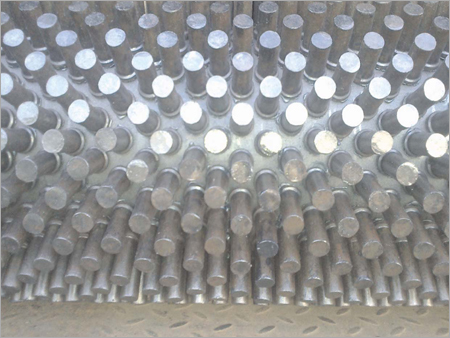

Extruded Finned Tubes

Product Details:

- Product Type Extruded Finned Tubes

- Material Aluminum (fins), Carbon Steel / Stainless Steel (tube core)

- Type Integral Extruded Fin Tube

- Shape Round

- Technique Extrusion

- Surface Treatment Anodized or Plain

- Standard ASTM A213 / ASTM A334 / DIN 17175

- Click to view more

X

Extruded Finned Tubes Product Specifications

- Aluminum (fins), Carbon Steel / Stainless Steel (tube core)

- Anodized or Plain

- 1.65 mm to 4.5 mm

- Extrusion

- Integral Extruded Fin Tube

- Silver / Metallic Grey

- ASTM A213 / ASTM A334 / DIN 17175

- Up to 370 MPa (Tube material dependent)

- Up to 15 meters

- Custom sizes available

- 12 mm to 41 mm

- Up to 63 mm

- Extruded Finned Tubes

- 304, 316, 321, 204 (Stainless Steel); Gr. A/B (Carbon Steel)

- Round

Product Description

Leveraging on our vast experience of this domain, we manufacture, supply, import and export high quality Extruded Finned Tubes. These tubes are manufactured under the guidance of experienced professionals, who employ modern machines and utilize quality tested material, obtained from authentic sources of the industry. All our Extruded Finned Tubes are stringently tested on different parameters and then forwarded for the end delivery to the clients.

Features:

- Longer life span

- Accurate dimensions

- Sturdy construction

- Perfect finish

- Having strong in construction

- Its durable structure makes it easy to install

- Compact built provides resistivity to adverse conditions

- Withstand high temperature due to strong structure

- Tough construction to bear high temperature

- Build with extra ordinary perfection

- Having anti-corrosive body

- Highly appreciated among clients for their high quality and perfect design

Outstanding Heat Transfer Efficiency

Engineered with high-grade extruded aluminum fins and precise fin geometry, these tubes maximize surface area and thermal conductivity. The result is superior heat exchange in industrial and HVAC settings, making them ideal for energy-saving and high-performance operations.

Customized to Your Requirements

We offer comprehensive customization, including fin height, thickness, tube diameter, and end type (plain, threaded, or flanged). Our manufacturing process supports industry standards such as ASTM and DIN, ensuring seamless integration into your systems and processes.

Durable in Extreme Conditions

The tubes deliver robust corrosion resistance, suitable for atmospheric and industrial environments. With anodized or plain surface treatment options and high-tensile strength tube cores, these finned tubes withstand temperatures up to 250C and aggressive operational settings.

FAQs of Extruded Finned Tubes:

Q: How are extruded finned tubes manufactured to achieve high heat transfer efficiency?

A: Extruded finned tubes are produced through an extrusion technique, bonding high-grade aluminum fins directly to the tube core (carbon steel or stainless steel). This process produces integral fins with uniform height and thickness (up to 16 mm and 0.30.5 mm), maximizing surface area and thermal conductivity for enhanced heat transfer.Q: What applications are extruded finned tubes commonly used in?

A: These tubes are widely utilized in heat exchangers for the oil & gas sector, chemical plants, HVAC refrigeration units, and numerous industrial processes demanding efficient thermal management and durability.Q: When should I choose finned tubes with custom dimensions or finishes?

A: Custom finned tubes are recommended when your system design requires specific lengths (up to 15 meters), diameters (up to 63 mm), end types (plain, threaded, flanged), or unique surface treatments (anodized or plain). This ensures compatibility and maximized operational efficiency for your application.Q: Where can extruded finned tubes be deployed for optimal benefits?

A: Optimal deployment includes industrial environments prone to corrosion, high thermal demand areas in heat exchangers, process heaters, and HVAC installations where stable performance at elevated temperatures (up to 250C) and reliability are required.Q: What is the packing process for safe export and delivery?

A: We use wooden boxes or seaworthy export packaging to securely transport finned tubes, safeguarding them against mechanical damage and corrosion during transit. Specialized packing methods are applied for international shipments to maintain product integrity.Q: What are the benefits of using high grade aluminum for fins?

A: High-grade extruded aluminum fins offer excellent thermal conductivity, efficient heat transfer, and superior corrosion resistance. This minimizes maintenance costs and improves system longevity in demanding atmospheric and industrial settings.Q: Can the fin and tube specifications be fully customized for specific projects?

A: Absolutely. Fin height, thickness, density, tube diameter, length, material grade, end configuration, and surface treatment can all be tailored in accordance with client specifications to optimize performance for any unique application.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email